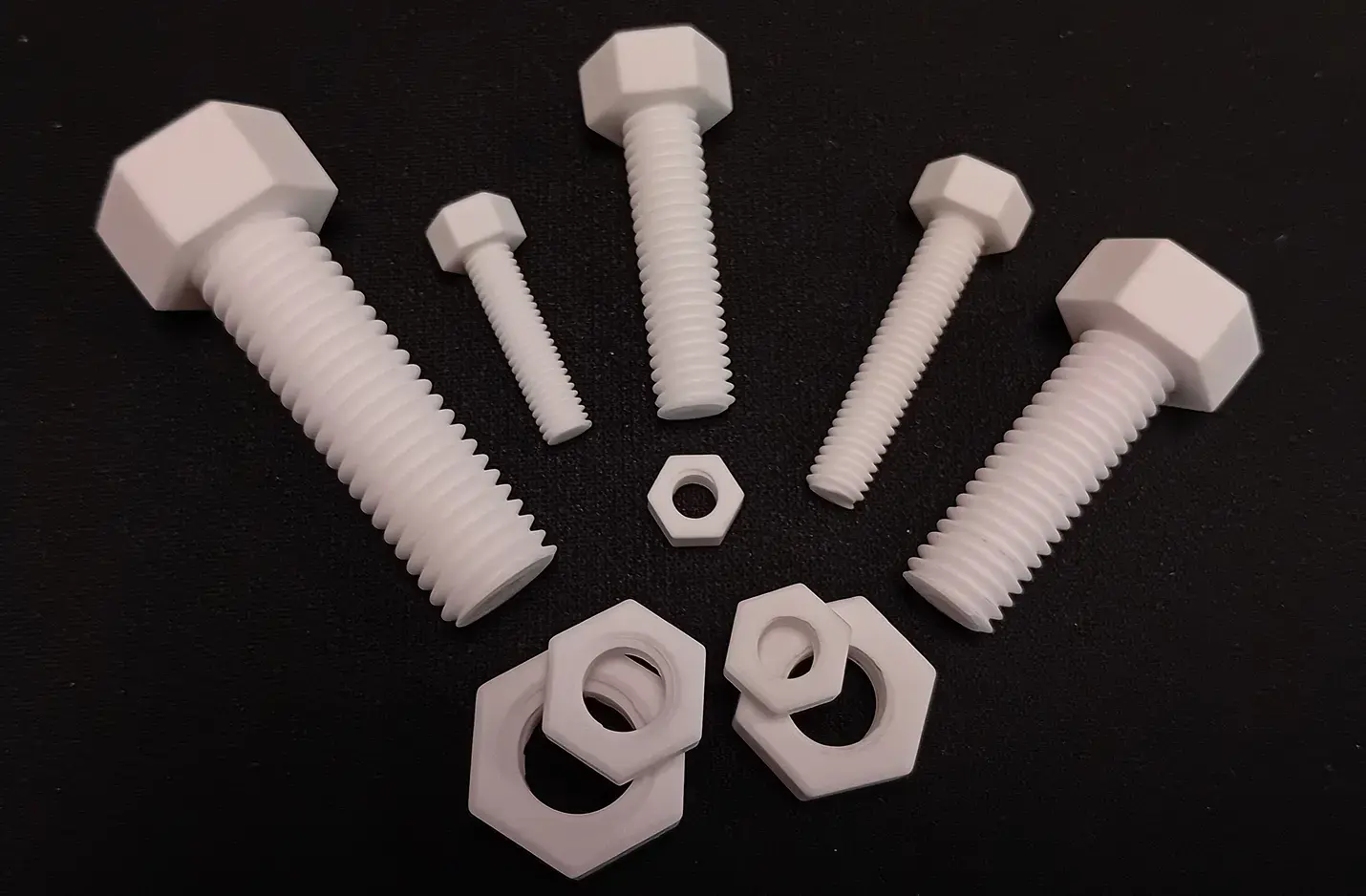

Cutting-edge engineering? The key lies in the use of advanced ceramic screws.

Ceramic screws made from 96% alumina offer a sustainable solution that combines safety, durability, and resistance to critical operating conditions.

Ceramic screws are fastening elements manufactured from advanced technical ceramics, primarily high-purity alumina (aluminum oxide) or silicon carbide. These components are characterized by high hardness, electrical insulation, and exceptional heat resistance, offering superior performance compared to traditional materials. They retain their mechanical and structural properties unaltered up to 1400°C, although continuous operation is recommended within the 1200°C range. This thermal stability makes ceramic screws ideal for high-temperature environments where other materials may deform, oxidize, or lose structural integrity.

Another key advantage is their corrosion resistance. Ceramic screws are chemically inert and resistant to acids, alkalis, oxidation, and saline exposure. This makes them well-suited for corrosive or outdoor environments, such as marine, petrochemical, or harsh weather conditions. Unlike metallic materials, ceramics do not degrade due to corrosion and do not require protective surface treatments.

With a specific weight of approximately 3.5 g/cm³, ceramic screws are significantly lighter than their metal counterparts. They offer good mechanical strength and can withstand high tightening torques, ensuring safety in demanding, high-stress applications where electrical insulation and non-magnetic behavior are critical.

An advanced technical choice for those seeking reliable solutions under extreme conditions.

An underrated solution, perfectly suited for engineering

Many engineers are unaware of the existence of ceramic screws, yet they represent a superior technical solution in numerous applications. Moreover, thanks to the DIN 40-680 standard, dimensional tolerances and deviations are strictly regulated, ensuring reliability even in the most critical projects.

Main applications.

Aerospace

Thanks to their light weight, electrical insulation, and heat resistance, ceramic screws are used in high-temperature electronic systems and components subjected to extreme stresses.

Electronics

They ensure insulation, non-magnetic properties, and interference resistance—essential in high-precision devices where even minor electrical leakage can cause malfunctions.

Medical

Non-magnetic and completely inert, ceramic screws are employed in medical equipment to guarantee safety, sterilizability, and environmental protection..

Photovoltaics

They deliver excellent performance under high temperatures and voltages, maintaining electrical insulation and chemical resistance in harsh environmental conditions.

Petrochemical Industry

Ceramic screws withstand aggressive substances, high pressures, and temperatures, helping to extend the service life of plants and equipment.

Communication

Used in transmission devices where electrical insulation and safety against electromagnetic waves are essential.

Savar is the ideal partner for your ceramic components.

With expertise dating back to 1977 and a constant commitment to quality, we offer high-performance, reliable, and sustainable ceramic screws. Manufactured from 96% alumina, they are designed for applications where traditional metallic materials cannot ensure safety, durability, or compatibility with critical environments. Furthermore, the design of ceramic screws can be fully tailored according to specific customer requirements—from head types (hexagonal, Allen, etc.) to thread pitch and diameter (recommended not below M4).