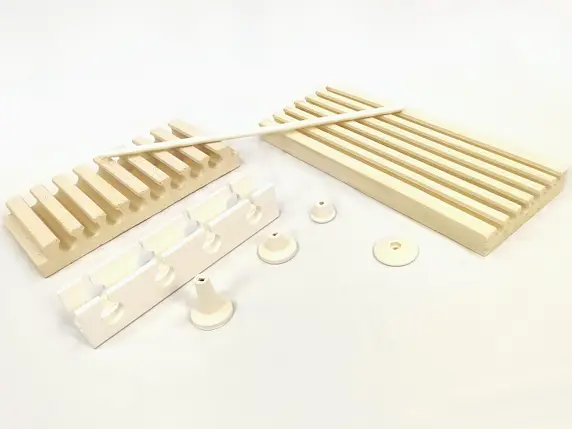

Technical ceramic bodies: far more than simple compounds.

Discover how high-performance technical ceramic bodies are created, custom-engineered to meet the specific demands of industry. From the controlled selection of European raw materials to the most advanced production processes. A guide that reflects expertise, innovation, and reliability in support of your most complex projects.